WHY COMPACTION OF

According to FHWA and the Asphalt Institute, proper compaction is one of the most significant factors in improving the life of an asphalt pavement.

Every 1% better compaction leads to at least 10% extended pavement life. By achieving just 2% better compaction uniformly throughout a roadway can lead to the roadway lasting at least 20% longer!

Using Paver Mounted Thermal Profiling and Intelligent Compaction to monitor temperature profile and compactive effort drastically improves compaction quality and consistency by overcoming the wide variations typical of human operators.

Temperature Profile

Proper temperature of the mix must be maintained both during placement and throughout compaction. The temperature should be uniform with minimal to no thermal segregation. By combining Paver Mounted Thermal Profiling and Intelligent Compaction allows verification that the timing of the compaction of the asphalt pavement occurred at the appropriate temperature. The time available for compaction is variable, impacted by:

- Air Temperature

Higher air temperature allows more time - Surface Temperature

Surface temperatures transmit temperature more quickly than air. More temperature is lost to the base than air - Mix Temperature

Higher mix temperature allows more time - Mat Thickness

A thicker lift retains more heat and allows more time - Solar Flux

Sunny days allow more time than cloudy days - Wind

Higher wind, less time - Precipitation

Rain causes the mat to cool off quickly allowing less time

Compactive Effort

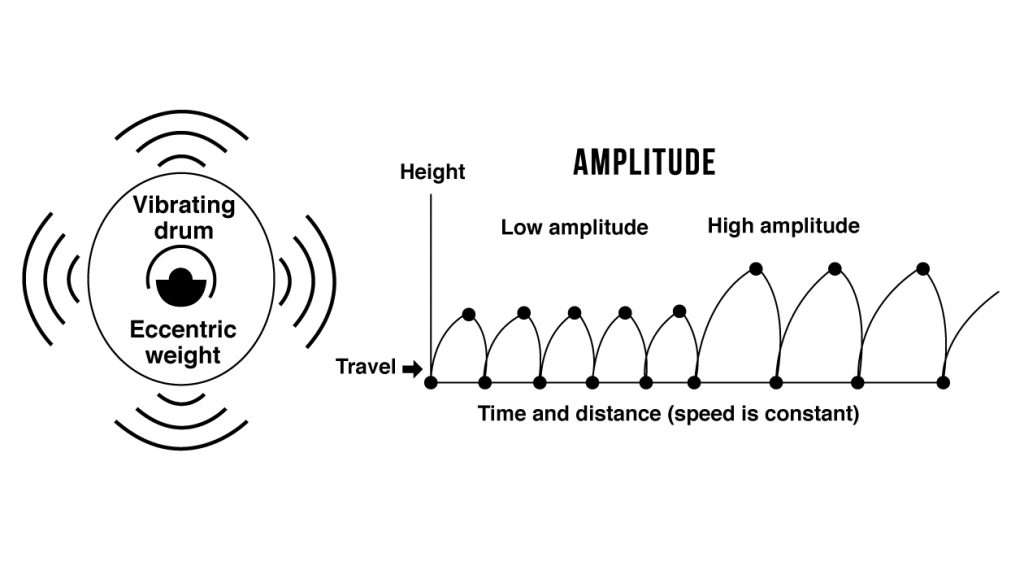

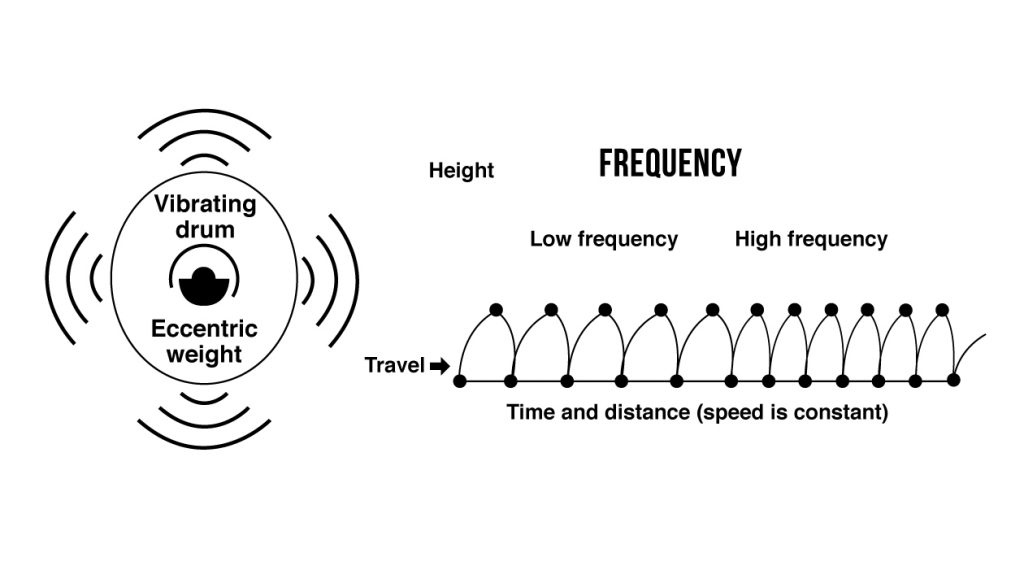

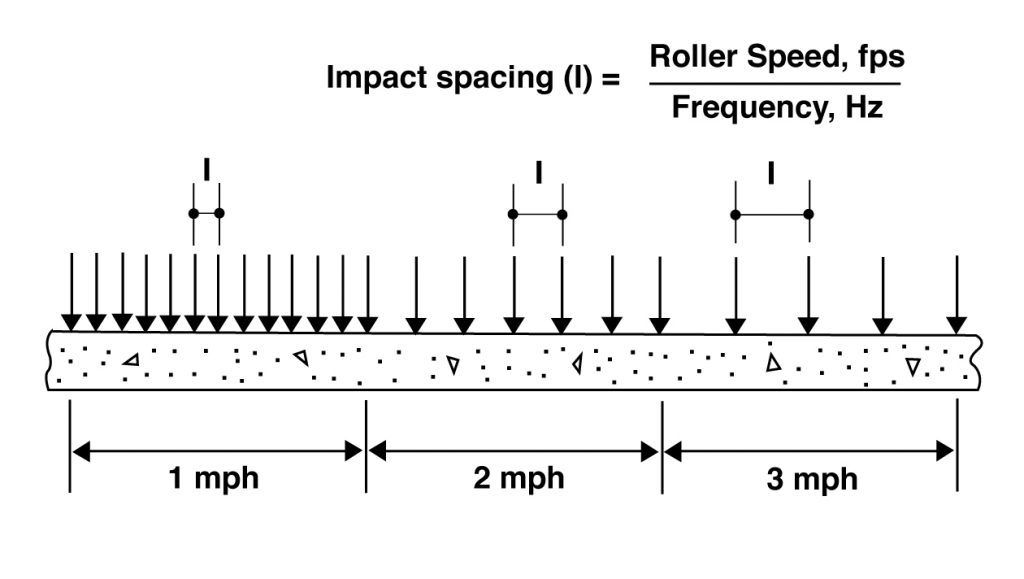

There should be adequate rollers both in weight and number to achieve compaction. Compaction should be applied uniformly throughout the roadway. Optimum rolling patterns should be developed to maximize compaction which includes coverage, number of passes and applying optimum amplitude (how hard the pavement is hit, force and depth) and frequency (number of hits per linear foot as the roller travels). The speed of the roller should be tied to optimum impacts per foot. The faster the roller travels, the less impacts per foot. This may be detrimental to both compaction and smoothness. The optimum impact rate is typically 10 to 12 per foot.