To improve quality, extend pavement life and reduce future maintenance costs of asphalt roadways:

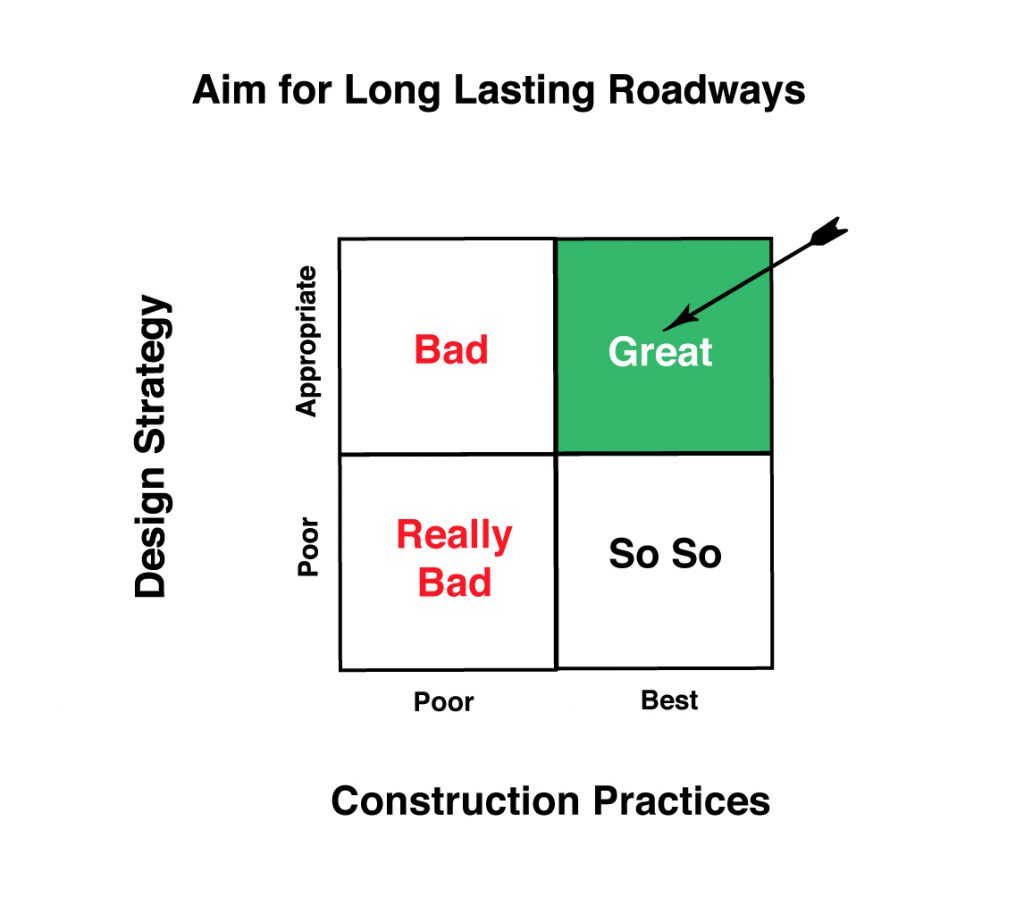

1. Construct the Roadway Properly

2. Properly Design the Roadway

A well-constructed roadway can perform well despite minor design deficiencies. However, even a perfectly designed roadway will not perform well if it is constructed poorly.

To make a roadway last, ensure it is built properly!

Good contractors use best paving practices and strong quality control (QC) when constructing asphalt pavements. The challenge for an Agency is that not all Contractors are good and even good contractors are not able to monitor their operations 100% of the time.

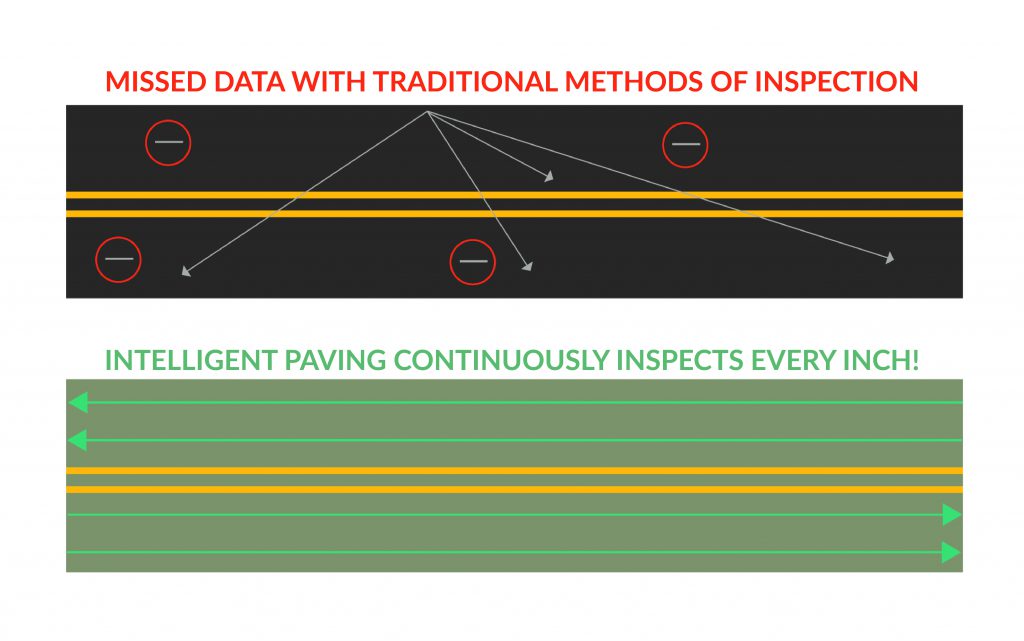

Agencies try to ensure quality by conducting their own quality assurance (QA), but QA is typically based upon human observations and isolated sampling and testing. Inevitably, the majority of new pavement does not get tested and/or observed.

Use Intelligent Paving for Agency QA monitoring or require it for a Contractor’s QC program to:

- Verify that asphalt placement is to Design

Ensure line, grade, cross slope and thickness - Monitor and improve Compaction

The most important factor in improving pavement life - Monitor and minimize Segregation

A major contributor to potholes - Measure and improve roadway Smoothness

The number one complaint of the public - Measure macro texture for an estimation of Friction

A major safety consideration

Intelligent Paving provides the ability to monitor the project remotely without sacrificing quality (Inspector-free Jobsites) by:

- Providing 100% data coverage of the roadway with no overlooking isolated defects

- Providing real-time monitoring of many quality parameters remotely via the cloud

- Allowing the daily download of performance dashboards summarizing construction quality

- Minimizing operator error – No more manual readings

Properly Designing the Roadway

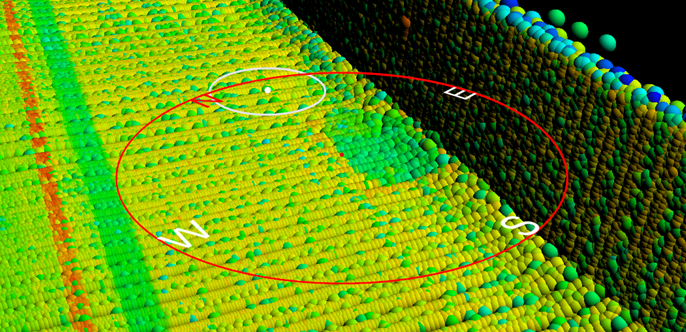

Pavement design should consider geometric conditions and requirements including drainage, cross slope, longitudinal profile, safety edges and tie-ins to existing pavements or structures. 3D modeling enables a designer to optimize geometric design for both the new construction and rehabilitation of pavements with better, more complete design information prior to and during roadway construction than traditional 2D deliverables.

The final surface should be smooth to provide comfort to road users even at high speed. 3D modeling and providing the design models to contractors for use in an automated machine guidance system provides a true BIM solution and leads to an optimized surface. Quality assurance of smoothness is verified using Inertial Profiling.

The pavement mix should provide adequate coefficient of friction to prevent skidding of vehicles. Inertial Profiling can be configured to measure macro texture and give an approximation of surface friction.

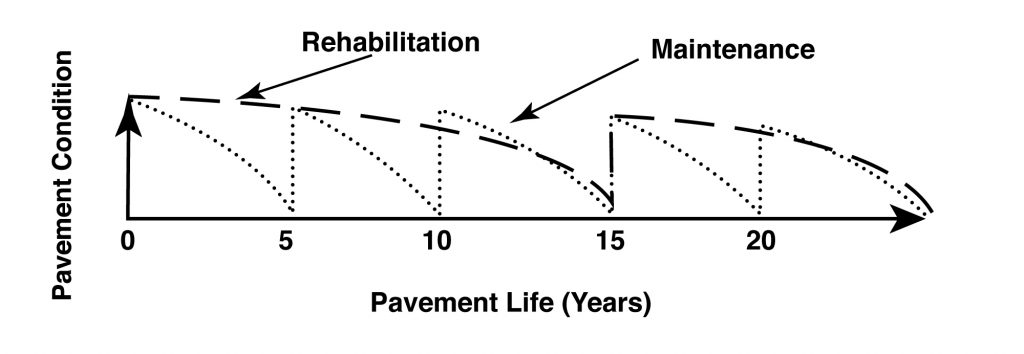

A structural design should be performed based on the anticipated traffic loading for the service life of the roadway.

For New Pavement Design:

The design should consist of a structural section that will support the anticipated loading expectations of future traffic volume, classification and truck weight data. The design needs to be structurally sound and of adequate thickness to distribute the wheel load stresses to a safe value on the underlying supporting sub-grade soil. The design must include proper drainage and a uniform, stiff, moisture and frost resistant foundation. The new roadway should include a shoulder structure providing edge support of at least 20 inches (0.5 m) in width from the traveled roadway edge.

For Rehabilitation Pavement Design:

An investigation should be performed on the existing pavement to evaluate the performance and establish the condition of the pavement with regards to traffic loading, environmental conditions, and pavement composition and thickness. The investigation should also identify the type and amount of distress in the pavement and the cause of the distresses. To gather as much information as possible and allow for proper engineering design considerations, the investigation should be multi-faceted to include both destructive and non-destructive testing.

For All Pavement Design:

The design should include an engineering and economic evaluation of alternative strategies and materials. The engineering evaluation should include consideration of the use of recycled materials and/or pavement recycling techniques. Economic considerations should include an economic analysis based on Life-Cycle Cost Analysis (LCCA) that identifies the long-term economic efficiency of competing pavement designs.